Maklumat produk

Penerangan Produk Terperinci

| Nama Produk: | Pemotong Laser Lembaran Logam | Laser Power: | 1000w 1500w |

|---|---|---|---|

| Panjang gelombang Laser: | 1080nm | Kawasan kerja: | 3000 * 1500mm |

| Pemotongan Ketebalan: | 0-16MM (bergantung kepada kuasa laser) | Bekalan Kuasa: | 380v |

| Waranti: | 1 tahun |

Desciption Produk

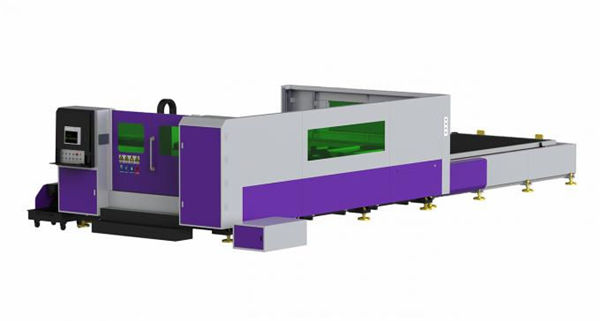

1. Reka bentuk mesin bersepadu: laci mengumpul dan kiri di sebelah kiri dan kanan mesin, ruang yang sangat menjimatkan.

2. Kestabilan dan kebolehpercayaan sistem dan sistem kawalan cahaya.

3. Serat laser mempunyai fungsi yang tinggi dan stabil dan jangka hayat yang melebihi 100000 jam.

4. Kualiti dan kecekapan pemotongan yang tinggi dengan kelajuan pemotongan sehingga 25m / min dengan canggih yang sempurna.

5. Pengurang prestasi tinggi, gear dan rak; Panduan Jepun dan skru bola.

Main Features of Sheet Metal Laser Cutting Machine

1. The middle part of the two platforms are not in the same level, which can Save time for feeding and unloading material in short time.

2. Fully enclosed design can greatly reduce damage to the health from the laser, especially for those countries who strictly required to the environmental protection.

3. The exchange platform with heavy capacity can be placed 8-10 mm carbon steel plate. The table has universal balls. There is a sheet metal clamping device beside the table, which can firmly fix the materials on the table to avoide workpiece movement.

4. If it was powered off or the chain was pulled off , the platform can be pushed in by hand. At the same time it has anti-collision protection device on the left side of the machine to protect of the machine from damaging.

5. Working platform plate was made of a thickness of 3 mm carbon steel plate, the service life is long. it dosen’t need the replacement in 8 months to 1 year.

6. The overall steel beam is very steel, the machine beam used a 17 mm thickness plate, and beam base’s thickness is about 30 mm.

7. Dust cover is made of the fire-retardant materials.There will not be break and pull off with a long time use, at the same time it can prevent the spark burning.

8. Using the well-known brand of Taiwan helical rack, Taiwan's silver (HIWIN) 30 rail, good quality electronic devices, and Franch drive motor to ensure the accuracy of the machine work.

9. Faster Acceleration , repeated positioning accuracy is about 0.03mm,and its cutting accuracy can reach 7-8 silk.

Technical Specifications

| Model | RL-1530F |

| Panjang gelombang Laser | 1080nm |

| Ketebalan memotong | 0.2-16mm |

| Kuasa output laser | 1000W |

| Julat pemprosesan maksimum | 3000 * 1500mm |

| Mod pemacu mesin | gear rak yang diimport dan memandu pinon |

| Y X. ketepatan kedudukan paksi | ± 0.01mm |

| Ketepatan kedudukan kedudukan paksi XY | ± 0.01mm |

| Mod bekalan kuasa | 380V / 50Hz |

| Kelajuan pemotongan maksimum | 45m / min |

| Lebar garis memotong minimum | 0.02mm |

| Mod penyejukan | 3P penyejukan air |

Butiran Mesin Pemotongan Laser

Bahan terpakai

Terutamanya digunakan untuk memotong keluli karbon, keluli silikon, keluli tahan karat, aloi aluminium, aloi titanium, lembaran keluli tergalvani, papan pengambilan, plat zink aluminium, tembaga dan pelbagai jenis bahan logam memotong dan sebagainya.

Industri Gunaan

Digunakan dalam pemprosesan logam lembaran, penerbangan, spaceflight, elektronik, peralatan elektrik, bahagian kereta bawah tanah, kereta, jentera, komponen ketepatan, kapal, peralatan metalurgi, lif, peralatan rumah tangga, hadiah dan kraf, pemprosesan alat, perhiasan, industri pemprosesan pembuatan.